Today I finally decided to fix up the Tandberg keyboard that I’ve been holding onto for some time now.

The board in question is a Tandberg TDV 5010, part of the 50XX series. The 5010 is the only model where the surplus keys are covered by blanks.

The blanked keys still work and output random letters from the QWERTY-layout upon contact.

The other two models, the 5000 and 5020, instead have dedicated keycaps for the NOTIS text system, developed by Norsk Data.

The keyboard itself didn’t look too bad, but it had some scuff marks along with a couple of non-working keys which made it rather hard to type with.

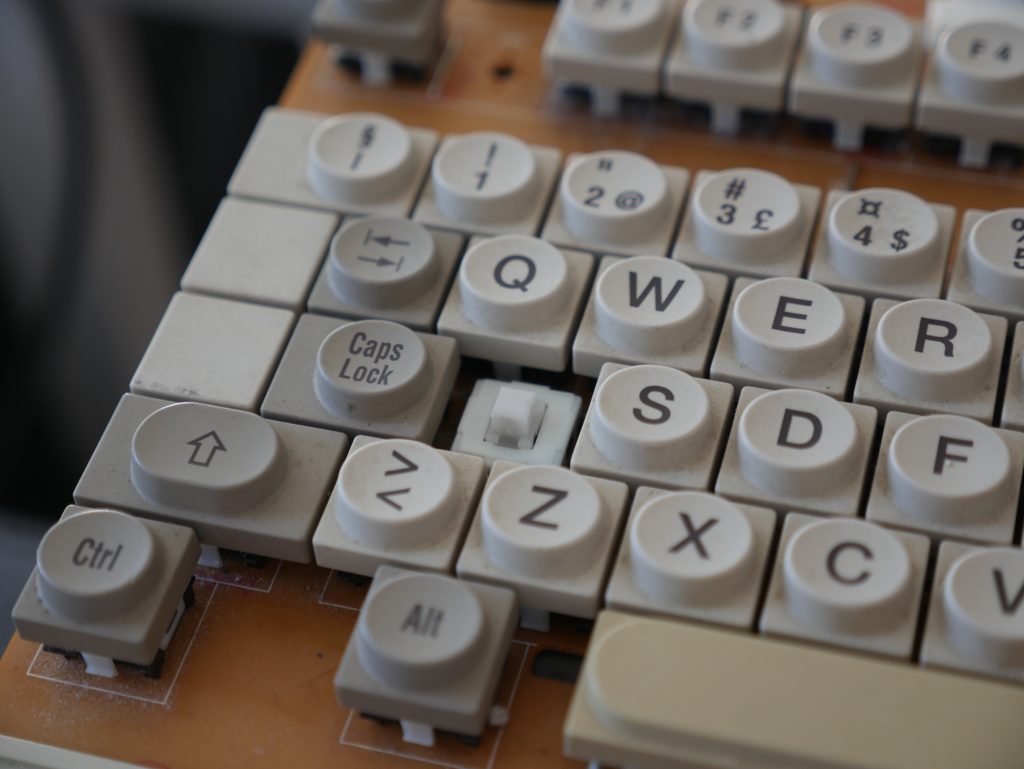

Although it appears clean from the outside, the keys hide decades worth of dust.

Yuck!

The first step was to look at the bad keys. The space-bar did not appear to function, and the culprit turned out to be a broken solder joint on the key switch.

I proceeded with scraping off some of the PCB to expose some more copper, and affixed the switch properly with hot glue. Easy!

The next key in question was the ‘A’-key. The traces connected to the keyswitch looked all good, and upon resoldering it, the key seemed to work again.

However, upon testing the keyboard I found that the key missed a lot of key presses. I swapped the switch with one of the other blanked keys, and sure enough, it worked again.

Below is a couple of pictures of the switches used in these boards, which are Siemens STB 21 switches (click the link to learn more about them)

They feel a bit like Cherry MX Brows, though with a more noticeable tactile feedback.

The next task was to clean the PCB itself.

After a couple of rounds with cotton swaps soaked in rubbing alcohol, the PCB now looks a lot better.

Although I could have taken the time to remove every switch and clean it thoroughly, I was happy with how it turned out with my minimal effort

The next part was cleaning the keycaps.

When I clean keyboards I like to be thorough as to remove as much dirt as I can.

To clean every key properly, I scrub them one by one with dishwasher soap.

This can really get tiresome, but the end result is worth it every time.

After scrubbing them, I rinsed off the soap using a pasta-tool (sorry, I don’t know what this thing is called)

Afterwards, I put them all on a blanket to dry and pointed my fan at them. Notice the funky way of using the cable for keeping the fan at an angle.

When all the keys were dry, I carefully replaced all the keys on the PCB and assembled the keyboard back together.

The top frame was also wiped off with a grease remover, along with rubbing alcohol to remove the worst scuffs.

This is the end result.

Although it might not seem like much of an improvement, the keys are definitely more comfortable to type with, in addition to all the removed dirt.

I also removed some pen marks found in various places on the board (so much for writing my name on it 10 years ago)

For now, this thing can continue towards another 30 years of service (or dust collecting, who knows..?)