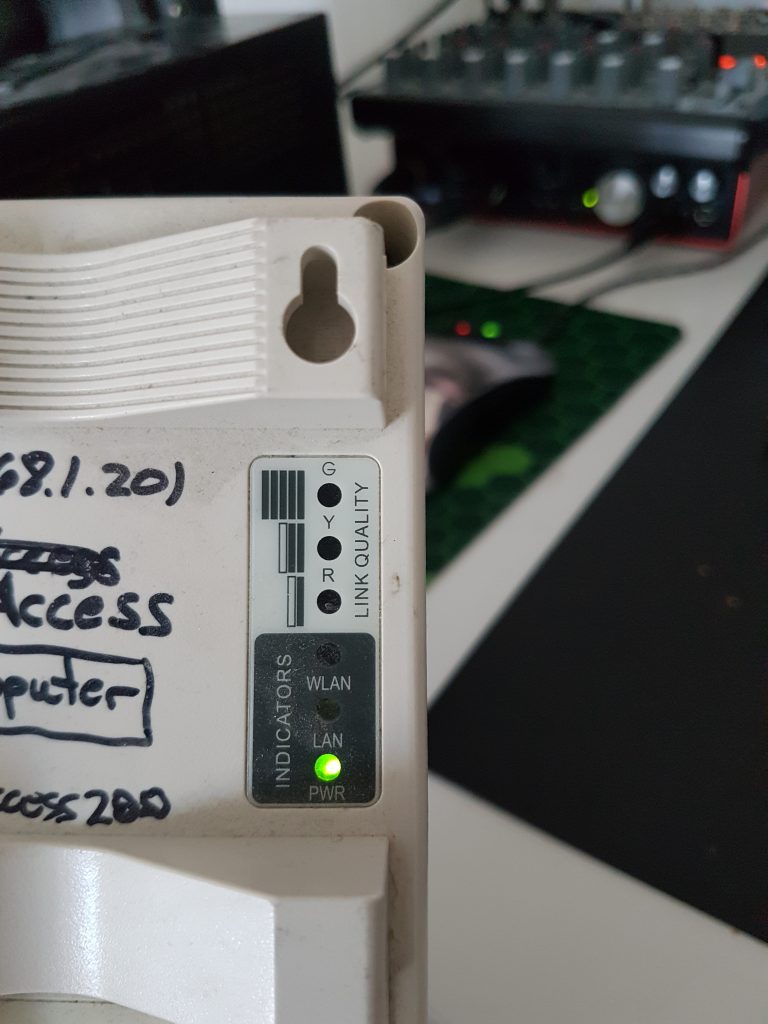

Recently I acquired a couple of EnGenius AP/p2p-bridges.

These require proprietary, passive PoE injectors, and since I didn’t want to invest any money into these, I decided to make my own.

They run of 24VDC, and utilize two of the pairs in an standard Ethernet-cable.

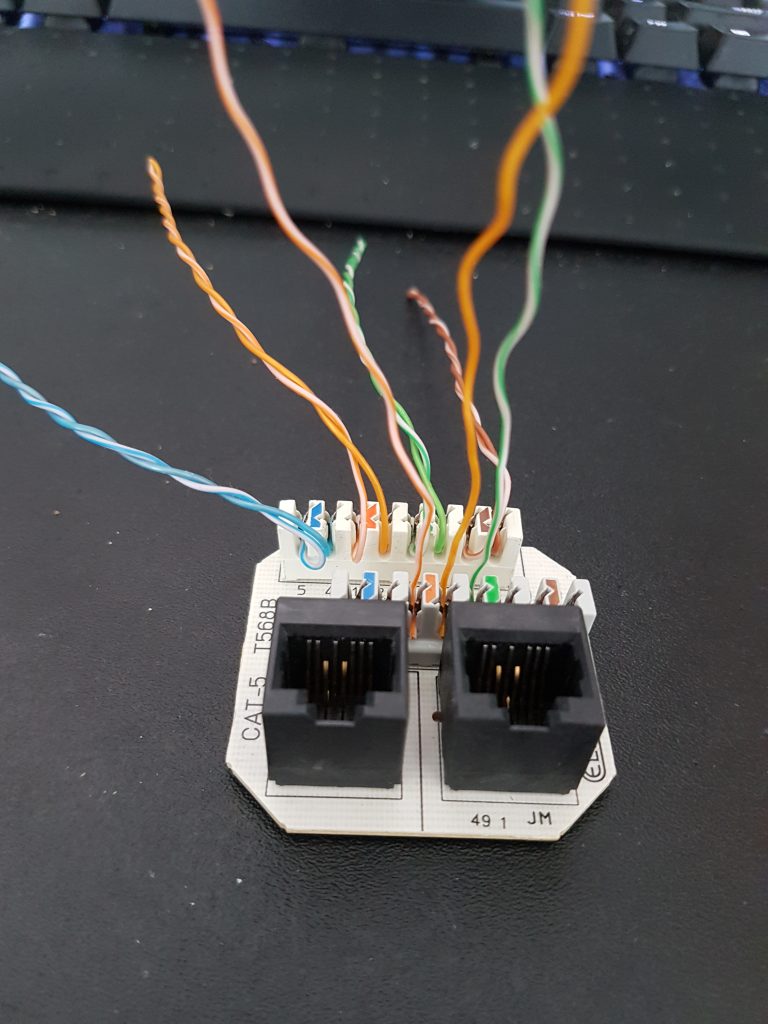

Making the injector itself wasn’t too hard. I based mine out of a double Ethernet-jack and some wire from a network cable

The jack already had some wires in it, so I simply removed the ones I didn’t need.

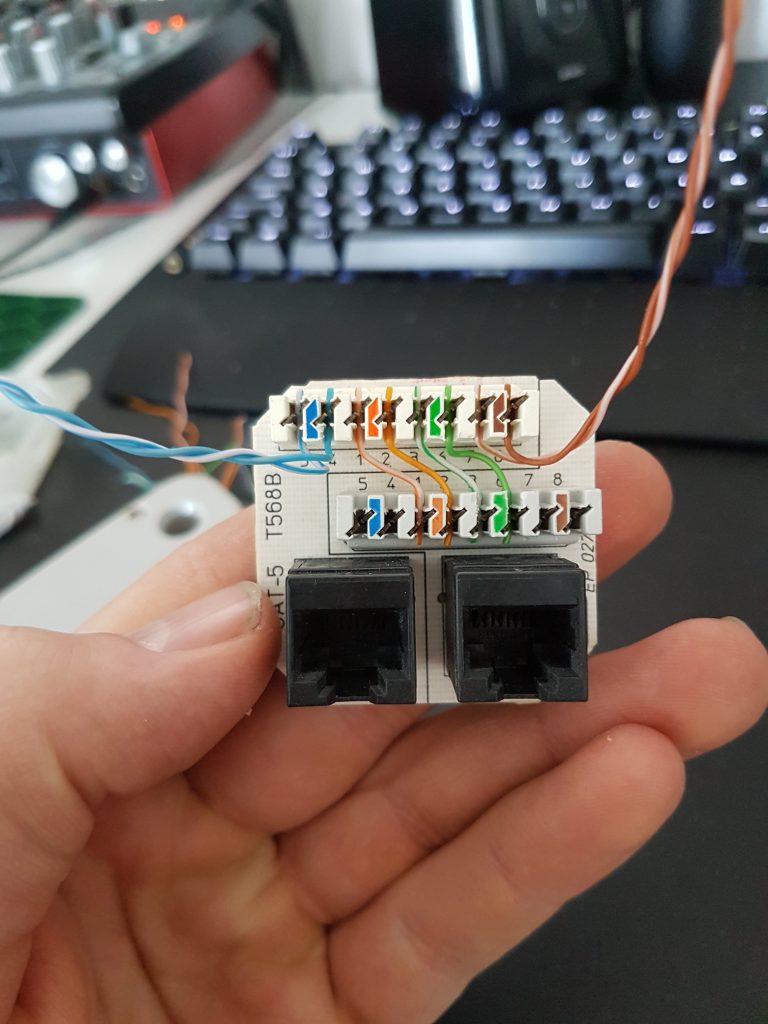

The orange and green pairs were used for Ethernet, as seen in the picture above. The blue and brown pairs were used to connect the power supply.

To minimize any wiring mess, I punched down short wires between the terminals for the two jacks.

For the PoE-jack I put in the two additional pairs (100Mbit Ethernet only requires two pairs) which supply 24V on pin 4-5 (positive) and 7-8 (negative)

This will in theory work the same way as a EnGenius EPE-1212 or similar. Just solder a DC-jack onto the powered pairs and apply your favorite 24VDC adapter to get going.

I will try powering these with Ubiquiti passive-PoE adapters as they seem to utilize the same pairs (and the same voltage) so they might be an easy drop-in replacement for the original ones (plus you don’t need to supply your own 24V PSU!)

Update: Ubiquiti PoE-adapters (the passive ones) work just as expected as they use the same standard for powering the device. So if you have lost the original power supply you can easily just purchase one to replace it.